Engineering fields

We create projects, solve problems, and help companies by offering our expertise and creativity.

We work in specific areas of engineering.

Krótki opis jak działamy w każdej z branż

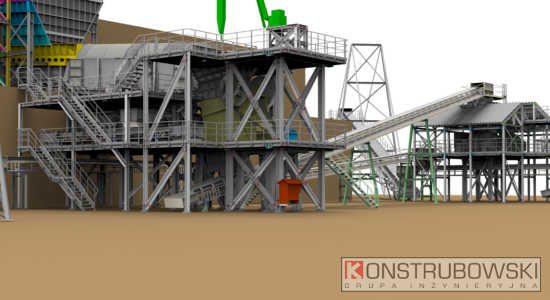

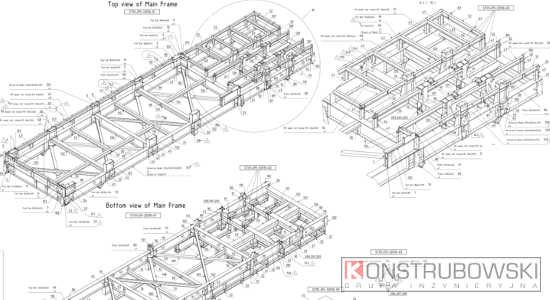

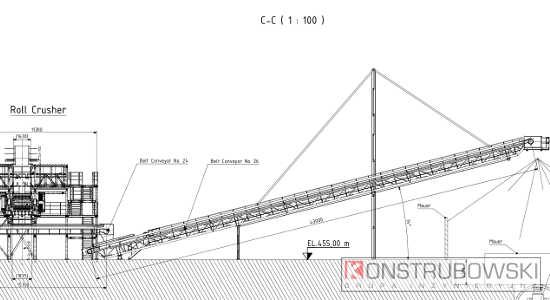

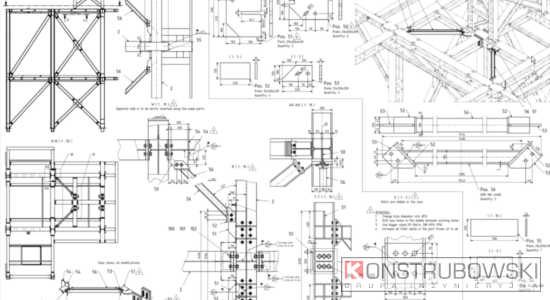

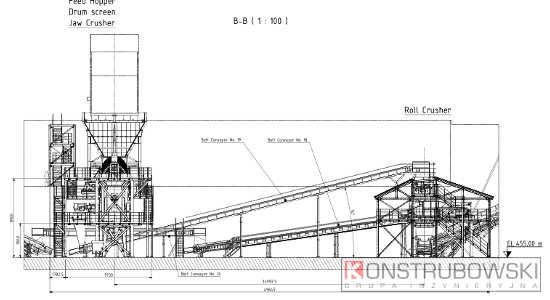

SURFACE MINIG

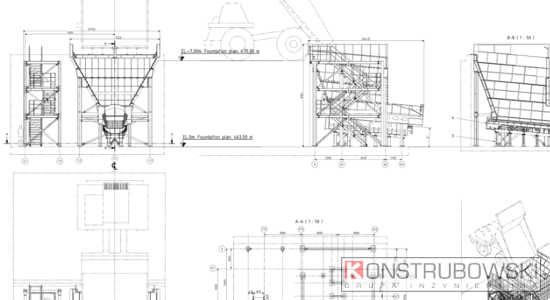

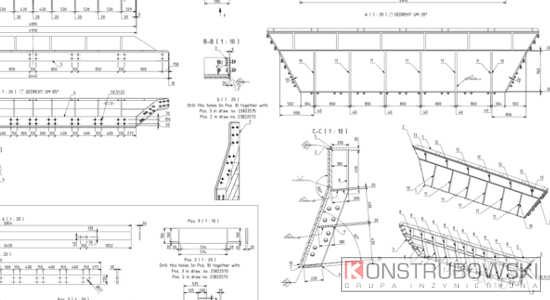

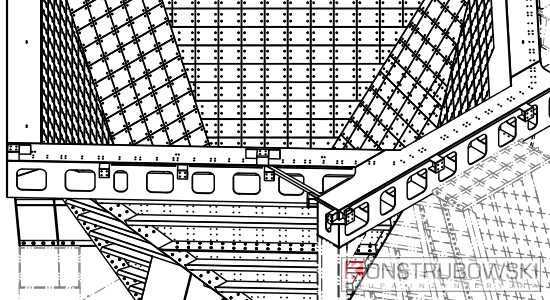

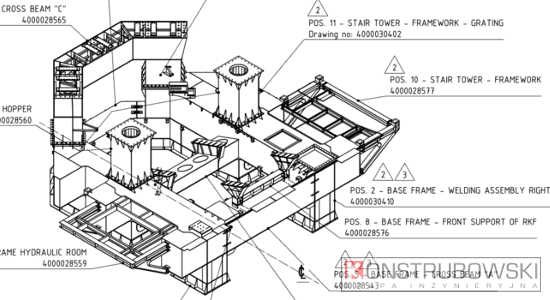

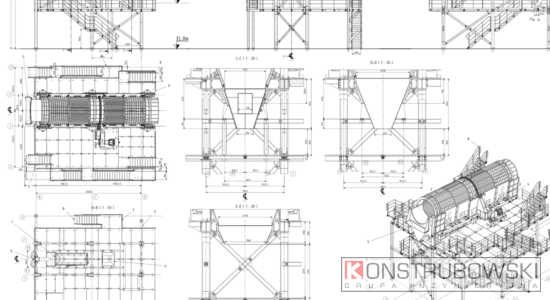

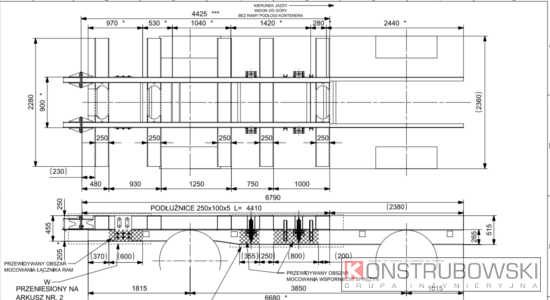

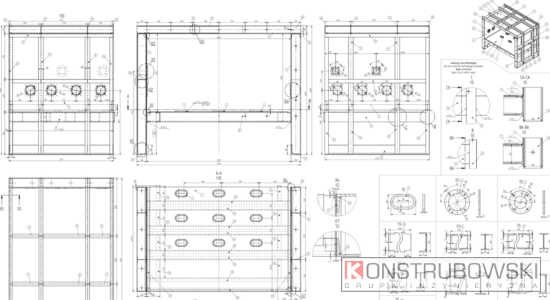

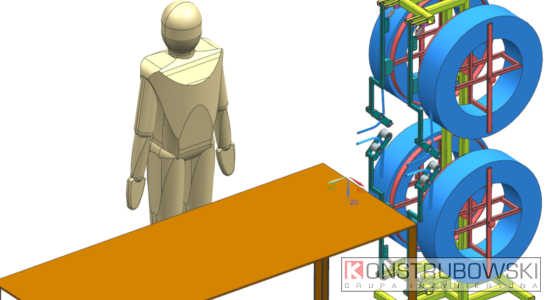

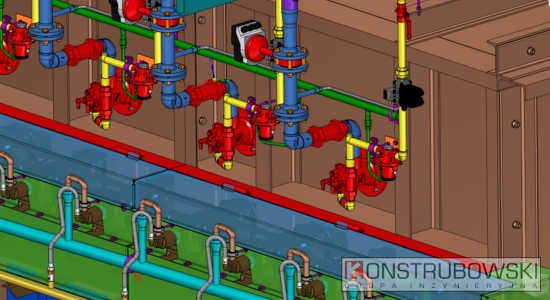

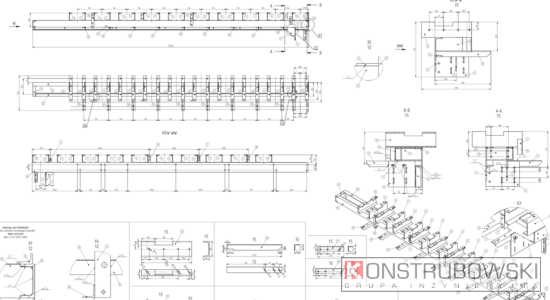

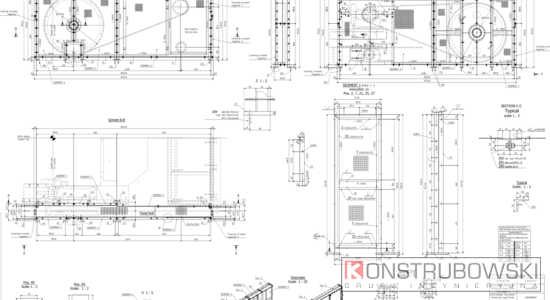

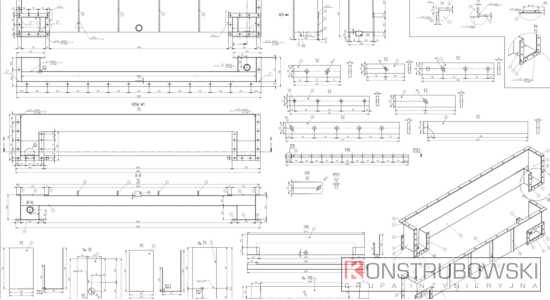

We specialize in designing rock crushing systems and stations (Crushing plant engineering) for projects located around the world. We design stationary and semi-mobile plants. On the basis of two-dimensional mine sketches (layouts) we prepare a complete design in 3D CAD environment (Detail engineering). We assist in cost estimation using rapid 3D modeling techniques (Basic engineering) combined with scripts that generate a bill of materials early in the project. The end result is high quality flat documentation (PDF/DWG), 3D model (any format) and bill of materials (MS Excel, Google Sheets).

In order to speed up the work on the project we have developed methods of parallel collaboration between designers using the secure and encrypted Google cloud.

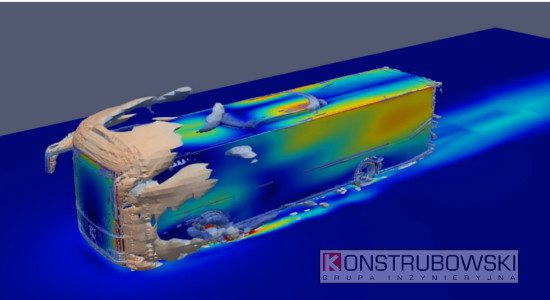

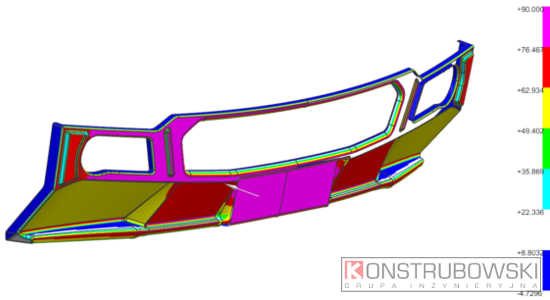

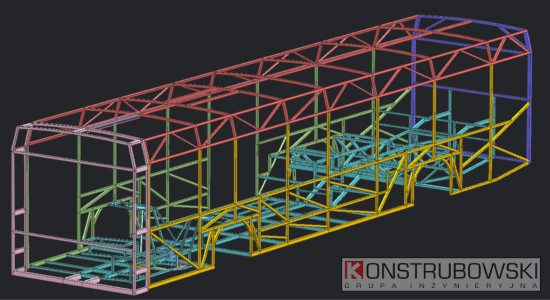

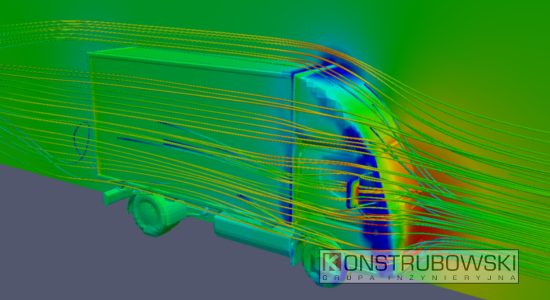

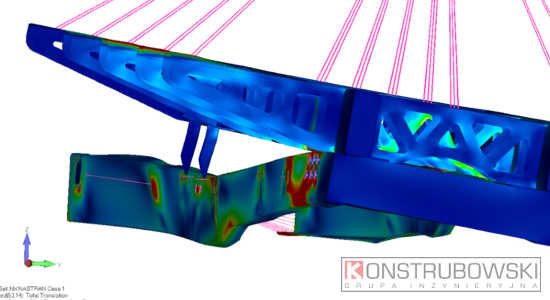

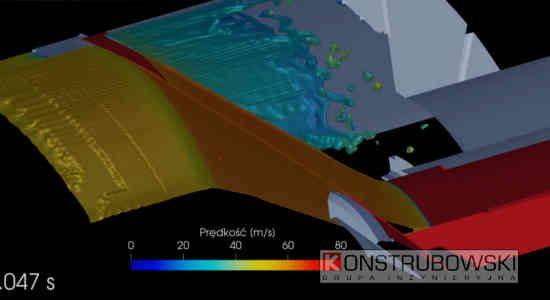

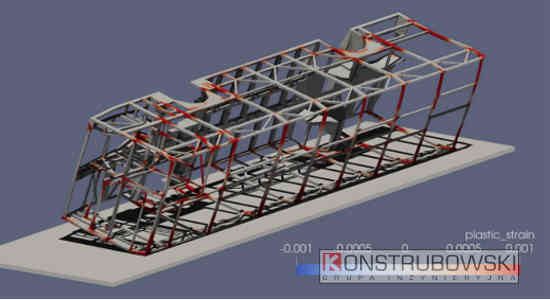

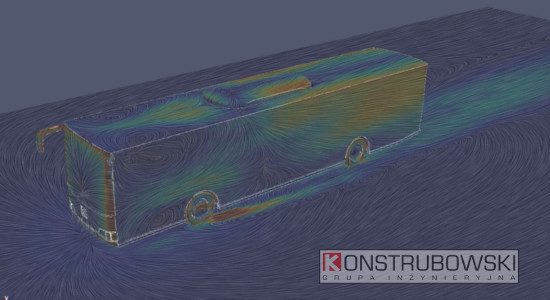

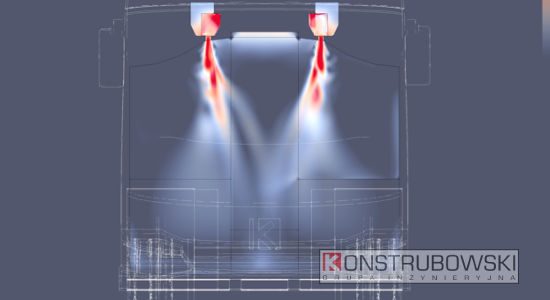

AUTOMOTIVE

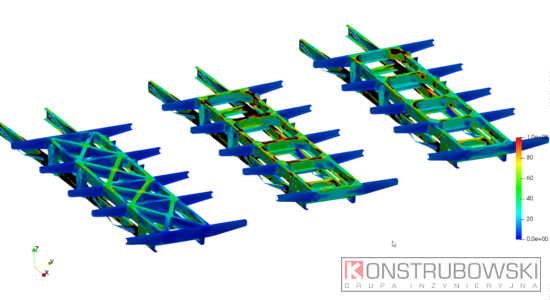

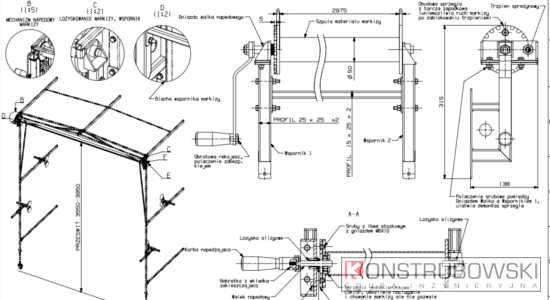

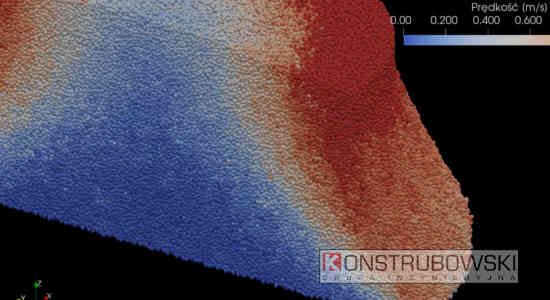

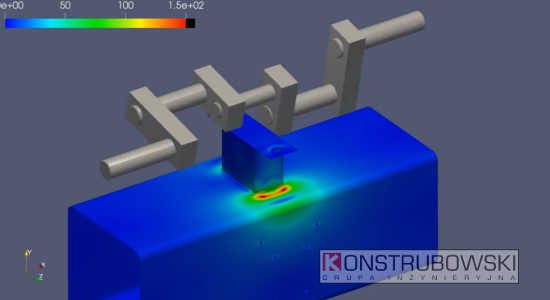

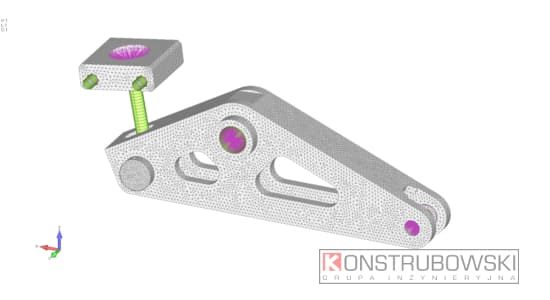

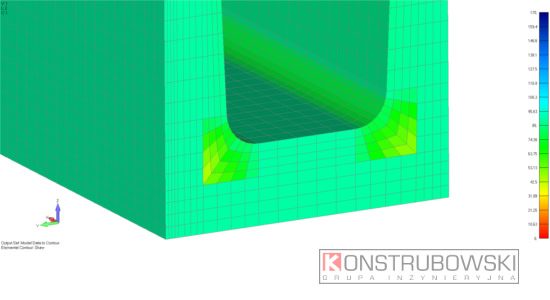

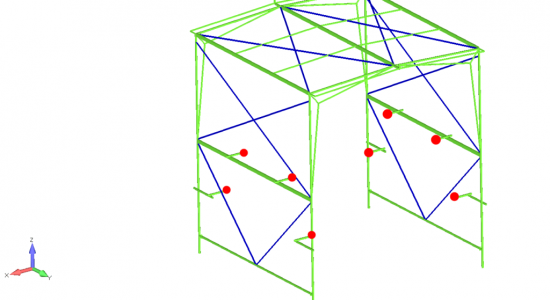

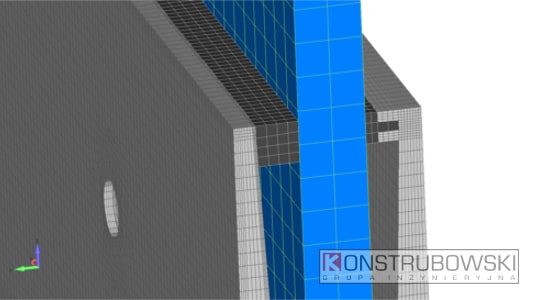

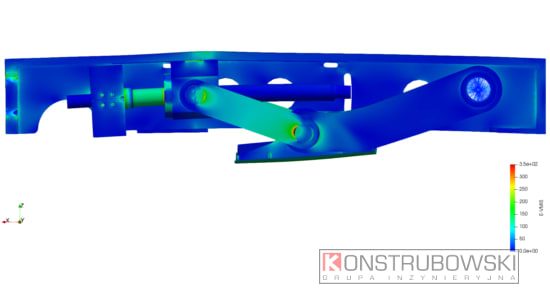

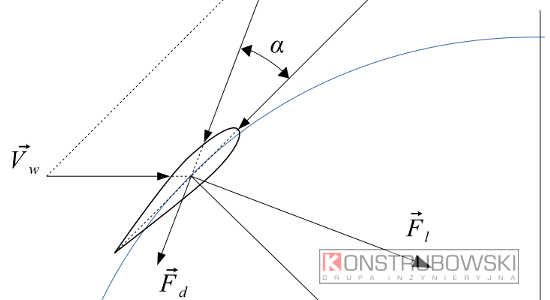

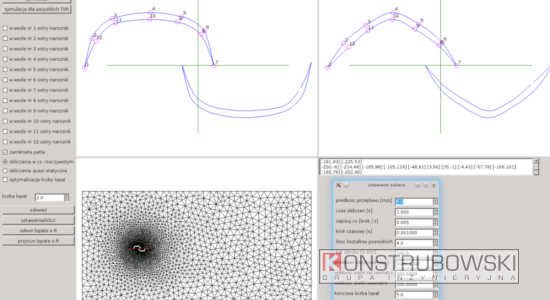

We have many years of experience in CFD simulations for the automotive industry. We determine the aerodynamic characteristics of the car body, reduce fuel consumption or side wall scuffing. We simulate HVAC systems (window, driver or passengers vents) and battery cooling simulations. We design elements of the vehicle exterior and interior (Class A surfaces). We support the designer’s work to jointly develop a technically feasible product. We perform designs of vehicle supporting structures (self-supporting frameworks, chassis elements) and check their strength by FEM simulation (linear, nonlinear, dynamic and fatigue). The most extensive experience has been gained during the design of city buses. We model in Siemens NX, Solid Edge, Inventor.

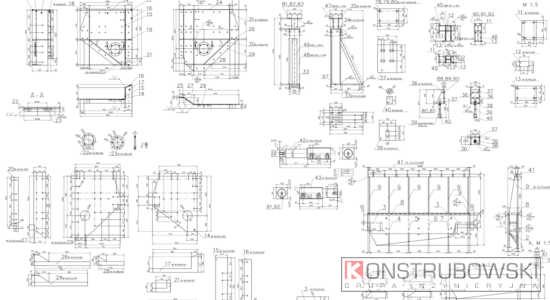

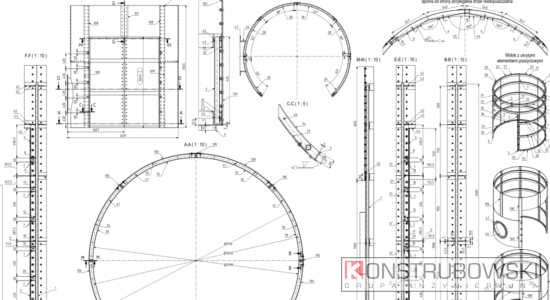

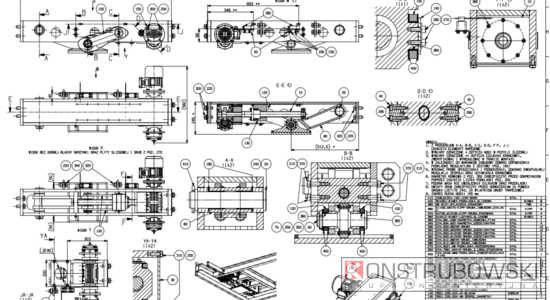

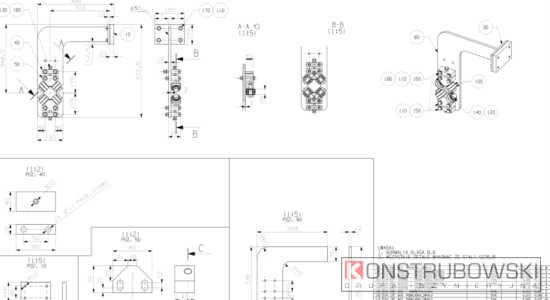

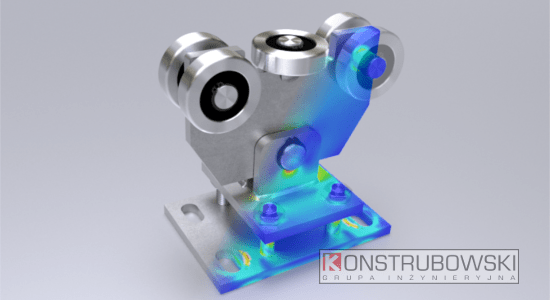

INDUSTRIAL MACHINERY | WASTE INCINERATION | MECHANICAL ENGINEERING

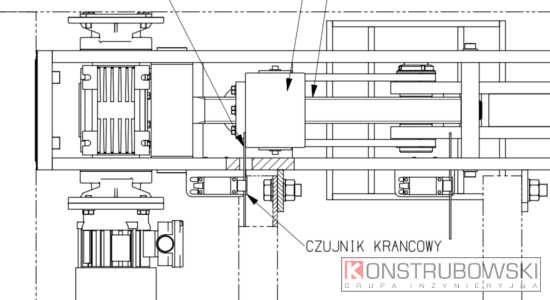

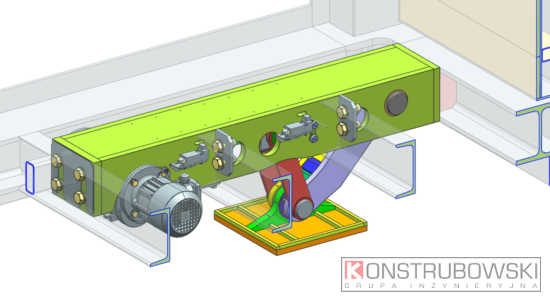

We design furnaces, lines and components for the heat treatment of metals. Examples include a titanium vacuum casting unit, a bar quenching furnace with a walking grate or a tube heat treatment line. We are open to other projects in the broad field of mechanical engineering.

The second large area of activity is waste incineration plants. We design loading chutes, movable and cooled boiler grate, heat exchangers, boiler air supply systems, ash pans, electrical installation.

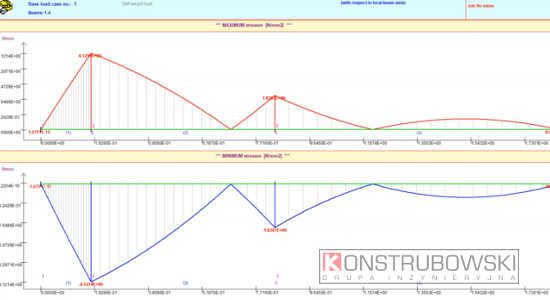

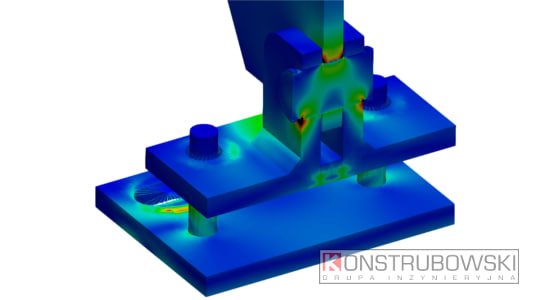

ENGINEERING CALCULATIONS

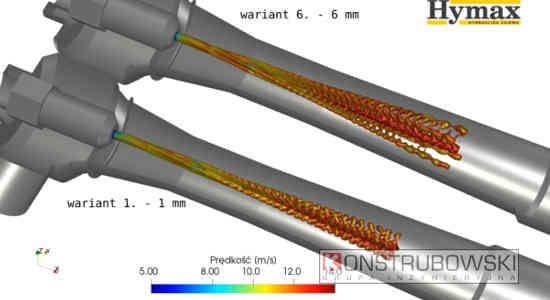

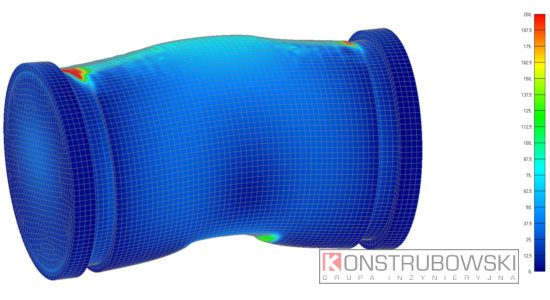

Calculations and simulations in fluid mechanics:

– Aerodynamics of vehicles and objects;

– Two-phase flows – simulations of nozzles, sprays, injectors;

– tank filling;

– HVAC simulation of vehicles;

– flows in piping and air ducts;

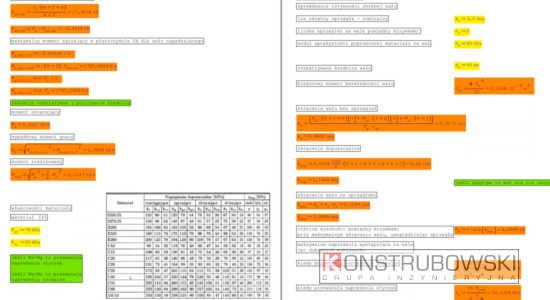

Strength of superstructures:

– FEA simulations: static, dynamic, linear, nonlinear, fatigue;

– Strength of bolted connections;

– Dynamic simulation of the strength of the vehicle superstructure (stresses in the structure during driving);

Simulations of loose materials: DEM;

PROJECT AND DOCUMENTATION MANAGEMENT

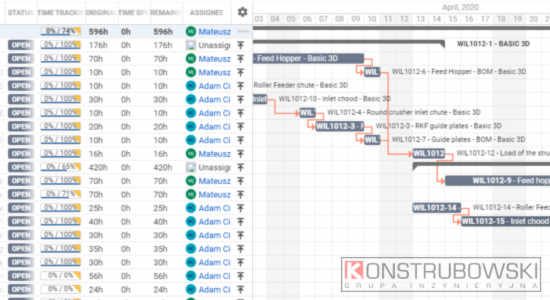

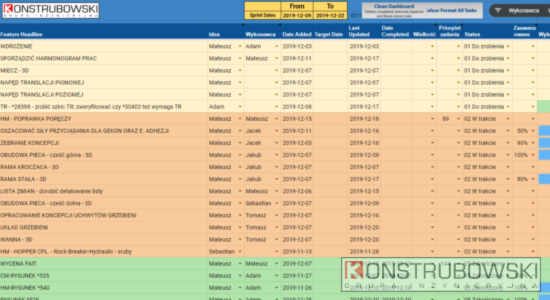

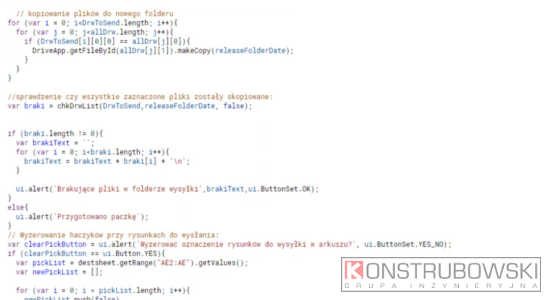

Most of our projects are large undertakings requiring several thousand hours of work. To keep the schedule under control we use the JIRA platform along with an extension add-on: BigPicture. For each project we build a Gantt chart and create detailed tasks for constructors. The client or contractor can have a real-time view of the project.

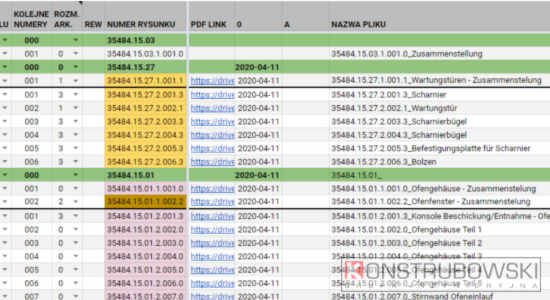

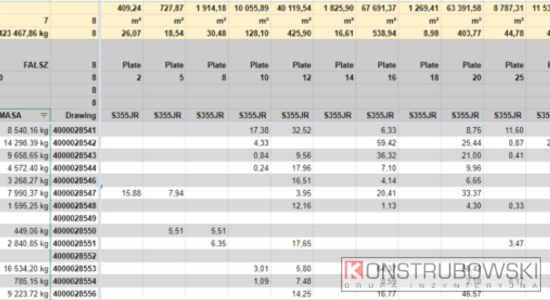

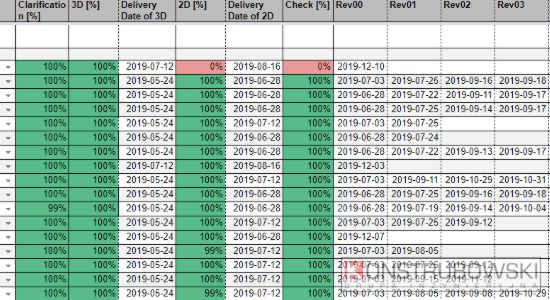

Large and complex projects mean a lot of technical documentation, 3D models and design guidelines. CAD modeling is supported by PDM systems and technical documentation and bills of materials are stored in secure and encrypted Google cloud. For each project we create tools that process project data from the cloud, creating a project management platform from ordinary Excel tables (G Sheets). We are able to quickly generate a table with the total surface area of metal sheets (divided into thickness) or sections from the entire project.

About

The team is made up of young people with a passion for engineering. We understand that solving problems is part of our job, so we are constantly looking for ways to solve them faster, which makes us happy. According to our standards, the project must be done accurately and flawlessly, we leave nothing to chance – every detail is verified. We know that designer’s work is a responsible job. We are creative and at the same time accurate as possible.

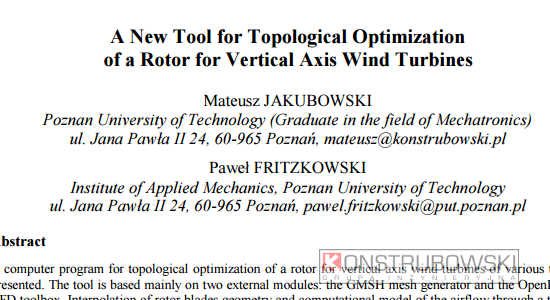

We work in: Siemens Solid Edge, Autodesk Inventor, Siemens NX, Siemens Femap, OpenFOAM, Autodesk Vault, Smath and other engineering tools. If necessary we create our own.

Co-founder

Experienced in the design of superstructures and self-supporting vehicle bodies. He analyzes engineering calculation results and leads a team of engineers. He is a PhD student at Poznan University of Technology.

Co-founder

Experienced strength computational engineer and designer of large-scale components. He leads the design team and deals with FEM simulations. Graduate of Poznan University of Technology

Kontakt

Mateusz: +48 509 704 251

Sebastian:+48 725 851 942